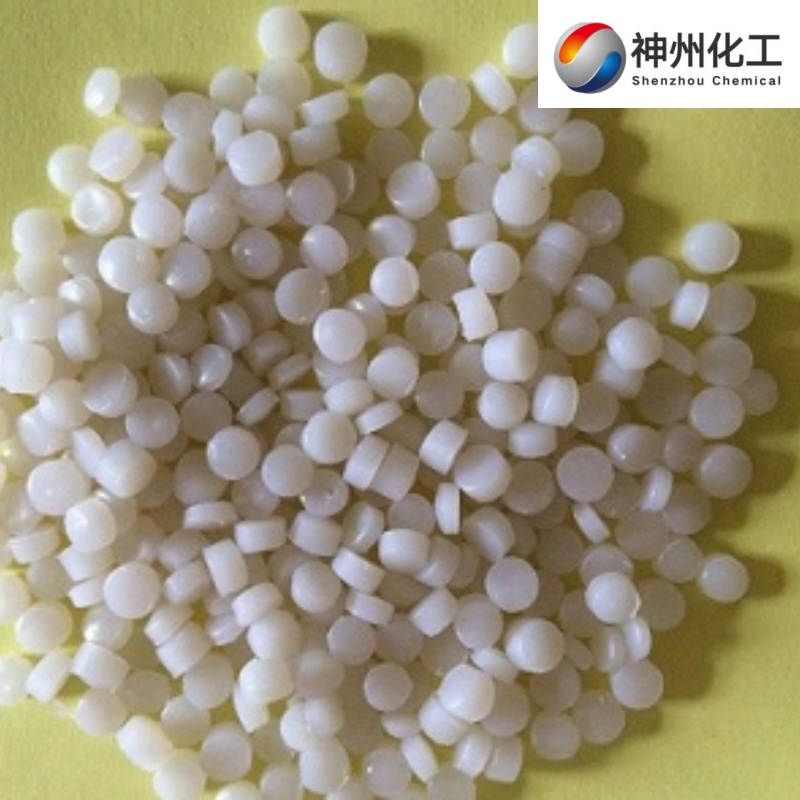

Product Details

Polyethylene CAS#9002-88-4

Polyethylene is a flexible, waxy, and translucent polyalkene thermoplastic, with its material properties being tailored by distinct production processes to meet diverse application needs. A representative synthesis route is the ICI process: ethylene gas containing trace oxygen is subjected to extreme conditions—pressure exceeding 1500 atmospheres and a temperature of 200°C—to form the polymer.

Commercially, PE is categorized into two primary grades based on density and structure:

Low-density polyethylene (LDPE, relative density 0.92)

It has a molecular weight ranging from 50,000 to 300,000, a softening point around 110°C, and a low crystallinity due to its predominantly atactic molecular structure.

High-density polyethylene (HDPE, relative density 0.945–0.96)

With a molecular weight of up to 3,000,000 and a softening temperature of approximately 130°C, it features higher crystallinity than LDPE.

In terms of performance and applications, polyethylene serves as an excellent electrical insulator, exhibits strong acid resistance, and can be easily processed via moulding and blow-moulding techniques, making it a staple in multiple industrial and consumer sectors.

Polyethylene Chemical Properties | |

Melting point | 92 °C |

Boiling point | 48-110 °C(Press: 9 Torr) |

density | 0.962 g/mL at 25 °C |

refractive index | 1.51 |

Fp | 270 °C |

storage temp. | -20°C |

form | powder |

color | White |

Specific Gravity | 0.95 |

biological source | rabbit |

Water Solubility | Soluble in acetone and benzene. Insoluble in water. |

Merck | 14,7567 |

Dielectric constant | 2.2(Ambient) |

Stability: | Stable, but breaks down slowly in uv light or sunlight. Incompatible with halogens, strong oxidizing agents, benzene, petroleum ether, aromatic and chlorinated hydrocarbons, lubricating oils. |

Surface tension | 35.7mN/m at 20°C |

NIST Chemistry Reference | Polyethylene(9002-88-4) |

IARC | 3 (Vol. 19, Sup 7) 1987 |

EPA Substance Registry System | Polyethylene (9002-88-4) |

Safety Information

Safety Statements | 22-24/25 |

WGK Germany | 3 |

RTECS | TQ3325000 |

TSCA | Yes |

HS Code | 39041090 |

Hazardous Substances Data | 9002-88-4(Hazardous Substances Data) |

Product Application of Polyethylene CAS#9002-88-4

Polyethylene (PE) is a thermoplastic polymer constructed from long-chain hydrocarbon molecules, and it boasts diverse applicability across multiple industrial and consumer sectors—including the production of flexible packaging films via the blown film extrusion process. In cosmetic formulations, PE also plays a functional role in modulating viscosity, enhancing suspension stability, and maintaining overall formulation consistency.

Its core application scenarios span a broad spectrum of injection and blow molding processes, as well as specialty coating and additive systems:

Blow and injection molded products: Toys, household utensils, and various lid components

Industrial/commercial injection moldings: Automotive seat components, lawn mower parts, and pail containers

Thin-wall injection molded items: Lightweight containers and daily housewares

Specialty additive/coating uses: Hot-melt paper coatings, additives for cast moldings, candle formulations, oil-based inks, and hot-melt adhesive systems

Factory and Equipment Show

Fast delivery time

Inventory 2-3 working days New production 7-10 working days