Polypropylene CAS#9003-07-0

CAS Number: 9003-07-0

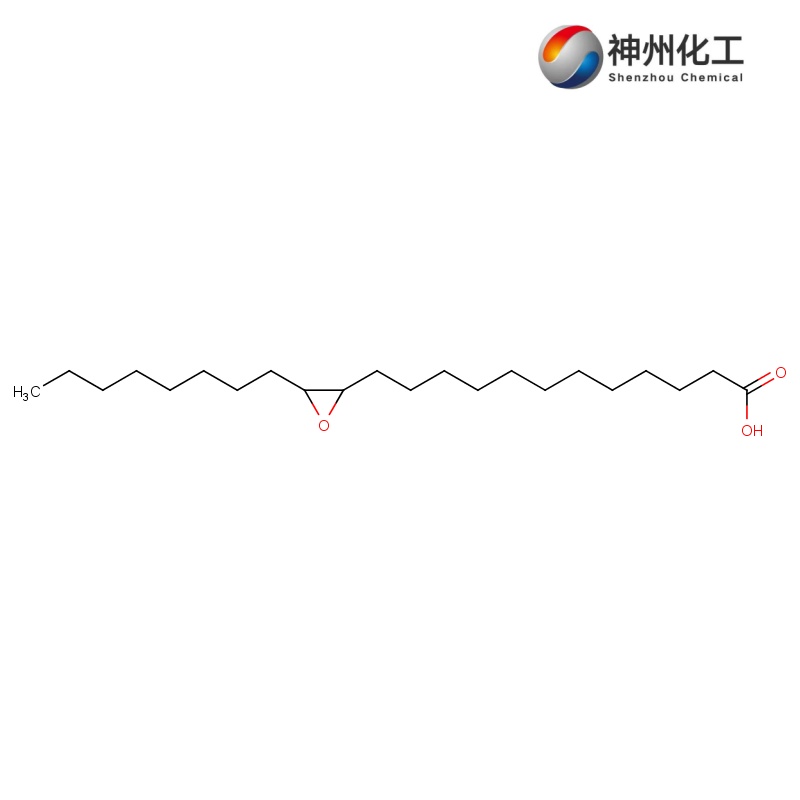

Chemical Formula: C22H42O3

Synonyms:

Polypropylene,film grade

Polypropylene master batch,flame retarding

POLYPROPYLENE, ISOTACTIC

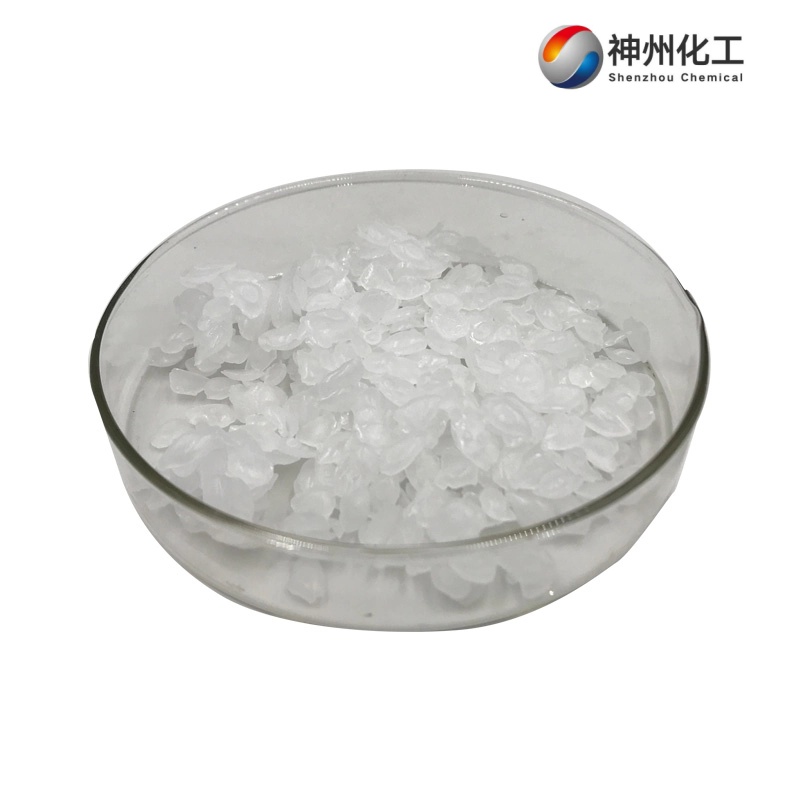

Appearance: White to off-white Solid

MOQ (Minimum Order Quantity): 1 FCL (Full Container Load)

Product Details

Polypropylene CAS#9003-07-0

Polypropylene is an atactic polymer that exists in both low-molecular-weight and high-molecular-weight grades, with distinct synthesis routes for each form:

Low-molecular-weight PP: Produced by passing propene gas over a phosphoric acid catalyst (supported on an inert carrier) at 200°C and moderate pressure. This reaction primarily generates propene trimers and tetramers, forming the low-molecular-weight polymer fraction.

High-molecular-weight PP: Synthesized by introducing propene into heptane (an inert solvent) containing a catalyst system of trialkylaluminum and a titanium compound. The resulting product is a blend of isotactic and atactic polypropylene, with isotactic PP accounting for the majority of the yield.

As a thermoplastic, polypropylene is widely utilized as a moulding material for various industrial and consumer applications.

Polypropylene Chemical Properties | ||

Melting point | 157 °C | |

Boiling point | 120-132 °C | |

density | 0.9 g/mL at 25 °C (lit.) | |

refractive index | n20/D 1.49(lit.) | |

Fp | >470 | |

storage temp. | -20°C | |

form | particles (Spherical) | |

color | red | |

Odor | odorless | |

biological source | human | |

Merck | 13,7663 | |

Dielectric constant | 1.5(Ambient) | |

IARC | 3 (Vol. 19, Sup 7) 1987 | |

NIST Chemistry Reference | Polypropylene, atactic(9003-07-0) | |

EPA Substance Registry System | Polypropylene (9003-07-0) | |

Safety Information

WGK Germany | 3 |

RTECS | UD1842000 |

TSCA | Yes |

HS Code | 39021000 |

Hazardous Substances Data | 9003-07-0(Hazardous Substances Data) |

Toxicity | LD50 intraperitoneal in rat: > 110gm/kg |

Product Application of Polypropylene CAS#9003-07-0

Polypropylene is an atactic polymer that is commercially supplied in two key grades differentiated by molecular weight, each produced via a dedicated synthetic pathway:

Low-molecular-weight polypropyleneThis grade is fabricated by subjecting propene gas to moderate pressure and a temperature of 200°C, with the gas passing over a phosphoric acid catalyst immobilized on an inert support matrix. The reaction selectively yields propene trimers and tetramers, which constitute the low-molecular-weight polymer fraction.

High-molecular-weight polypropyleneFor this grade, propene is introduced into heptane (an inert organic solvent) loaded with a binary catalyst system composed of trialkylaluminum and a titanium-containing compound. The resultant product is a heterogeneous blend of isotactic and atactic polypropylene, where isotactic PP dominates the composition as the primary component.

In terms of application, polypropylene’s thermoplastic properties make it a staple moulding material across industrial manufacturing and consumer goods production sectors.

Factory and Equipment Show

Fast delivery time

Inventory 2-3 working days New production 7-10 working days